Ever since the 1955 launch of the DS, Citroën have eschewed ordinary methods of springing their larger cars because of serious failings with the use of metal springs.

The problem

The major problem with conventional springs, which are fitted to the vast majority of cars, is that a spring becomes more compliant as the load on it increases. This means that the springing on an ordinary car has to be a compromise between when the car is empty and fully loaded. If the car is empty, the ride is harsh and if the car is fully laden, it sags and the handling is badly affected. This has a bearing on safety.

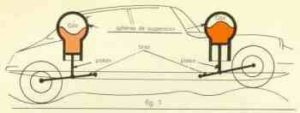

The Solution Citroën came up with the idea of using gas as a springing medium instead of metal. A gas becomes LESS compliant as the load on it increases. Thus the idea of springing the car on gas spheres was born. Each wheel has a gas pressurised sphere on it. Each sphere is divided into two internally. The upper part is filled with compressed nitrogen and the lower with LHM (Liquide Hydraulique Minérale), an incompressible mineral oil that is pumped around the system by a central pump. By altering the length of the fluid acting as a pushrod between the suspension arm and the sphere, the car’s ride height can be adjusted. This is done by a height corrector attached to each axle, which automatically keeps the cars height correct, regardless of load. The fluid is kept in a central reservoir and is pumped around the system by an engine driven, high pressure pump. The LHM also powers the brakes and the steering.

So, unlike conventional springs, an oleopneumatic Citroën drives virtually the same whether it’s empty or fully loaded. The ride height and the angle to the road (important for aerodynamic reasons) is kept constant. This has the side effect of keeping headlight beams at their correct angle to the road when towing a caravan or trailer which, on an ordinary car, would have the beams pointing dangerously upwards into oncoming driver’s eyes.

Furthermore, the driver can override the height by means of a selector lever inside the car. He can raise the suspension to cope with poor road surfaces and even minor fords. Another advantage is when you need to change a wheel – Simply raise the suspension to maximum, prop the car, lower the suspension – and the car lifts the affected wheel making it easy to remove. Other uses are when loading the boot or connecting a trailer. Simply lower the suspension to minimum and you hardly have to lift your heavy load into the car.

Furthermore, the driver can override the height by means of a selector lever inside the car. He can raise the suspension to cope with poor road surfaces and even minor fords. Another advantage is when you need to change a wheel – Simply raise the suspension to maximum, prop the car, lower the suspension – and the car lifts the affected wheel making it easy to remove. Other uses are when loading the boot or connecting a trailer. Simply lower the suspension to minimum and you hardly have to lift your heavy load into the car.

The common perception is that the system is unreliable, but the experience of most members of the Citroën Car Club is that is very reliable, providing that it is serviced properly. It is really this that accounts for Citroën’s reputation for comfort and ride quality. So impressed were Rolls-Royce, that they bought the system under licence to use for their own cars.

A question often asked is: what happens if there is a catastrophic leak? The answer is that the system is designed to fail in a predictable way. In the very rare event of a high pressure leak at speed, the first thing that goes is the power steering. This, together with a great big red ‘STOP’ warning light, immediately alerts the driver that something is wrong. The second thing to go is the suspension. The car’s ride will become poor as the body begins to sink. Only finally will the brakes be affected. Two points must be noted here. Firstly, any driver would realise that something was badly wrong in the early stages of a catastrophic leak and that this kind of leak is very rare. The tough American safety regulations recognise the Citroën system as being every bit as safe as a conventional system, if not safer. The one incident of this type that this writer knows of happened to a lady friend in her CX Safari on the M1. She has no technical knowledge, but immediately sensed that something was wrong (the big red STOP light and hydraulic pressure warning light coming on helped) and pulled over onto the hard shoulder without any fuss whatsoever.

It must be remembered that the system has its own backup in the form an extra sphere called the accumulator sphere. This is purely a reserve of pressure should a leak occur. It also acts as a buffer for the pump.

The system has been around for nearly 70 years, fitted to the rear of some very late production Traction Avants, and to every top-spec Citroën ever since – and is both tried and trusted. If it is maintained properly, it is more reliable and cheaper to run than a conventional system. And, of course, you get the tremendous benefits.

Citroëns fitted with hydraulic suspension :

- Traction 15/Six H (Rear only)

- H-van (Rear of some vans, usually Ambulances only)

- DS & ID

- SM

- GS & GSA

- CX

- BX

- XM (Hydractive I, later Hydractive II on all UK cars)

- Xantia (Hydractive II on top-spec UK cars)

- C5 Mk1 (Hydractive 3 or 3+ on all)

- C5 Mk2 (Hydractive 3+ on upper-spec cars, steel springs on lower)

- C6 (Hydractive 3 on 2.2, Hydractive 3+ on v6)

For more information on Hydractive suspension, please follow this link.